Tacoma once had a booming furniture-making industry that lasted more than a century and furnished homes around the world. It then all but disappeared with the rise of discount dining room and cabinet sets from Asia.

The industry evolved as a sibling of the area’s logging and sawmill operations. Tacoma’s chairs, desks and tables found themselves around the world thanks to the international shipping traffic through Commencement Bay and railroad tracks that connected to markets to the East.

“Furniture was sort of a natural extension of those (industries),” said local historian and researcher Edward Echtle. “I was surprised with how extensive it was because you don’t hear about it.”

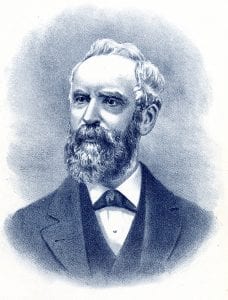

Tacoma’s furniture-making past dates back to the founding of the city itself. David L. Lister built Tacoma Foundry and Machine Co. at what is now the corner of 17th Street and Pacific Avenue in 1876 and quickly expanded the operation by making furniture. He would go on to sell the company to two other investors, who renamed it the Tacoma Furniture Factory right as Lister was being elected the first mayor of “New Tacoma” in 1881, before New Tacoma and Tacoma City merged three years later.

Carpentry shops large and small soon dotted the city, churning out crafted tables, chairs and bed frames as the city boomed. The most well known of those shops was the Fremont Smith Harmon and Co., which opened in 1882. The firm struggled to keep up with demand, so it bought out the Tacoma Furniture Factory in 1889 to become an industry giant of the Northwest. The company cornered the market on furniture and mattress making with satellite operations in Portland, Seattle and Spokane shortly after the turn of the century. Alan T. Crutcher and Joseph H. Kitlar bought the company from Harmon’s estate when he died in 1936. It was the second largest mattress maker on the West Coast, when it operated under a franchise agreement to make Serta Sleepers.

The fifth annual Northwest Furniture Manufacturing Exposition was held in 1926 and featured 50 Northwest manufacturers primarily from Tacoma, Seattle and Portland who displayed their products in showrooms in the Balfour-Guthrie dock. Photo courtesy: Tacoma Public Library

Other successful companies included the West Coast Chair Co., the Northwest Chair Co. and the Carman Manufacturing Co. The roots of Carman’s company actually date back to 1891, however, when it was the Pacific Lounge and Mattress Company. Joseph Carman bought and expanded it when he took over in 1903, which prompted a name change.

Tacoma-made dressers, beds, nightstands and even kit houses were listed in national catalogs and also shipped overseas. The industry boomed with the sounds of guns and cannons of World War II. The military found itself in need of office furniture in the far-flung reaches of Europe and Asia, as well as wooden parts for vehicles large and small. Harmon, for example, crafted seats for Boeing’s bombers and bunk beds for Army barracks. Northwest Chair Co. built wooden frames for supply trucks and supports for the Boeing B-17 and B-29.

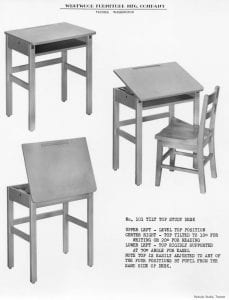

The emergency shift in products during the war years taught local woodworkers to remain nimble so they could change with customer demands, new materials and ever-fickle tastes in furnishings. The Educators Manufacturing Co., for example, formed in 1948 and made plywood cabinets for schools around the nation. The post-war baby boom meant school districts could barely keep up with the demand for new classrooms, and all those classrooms needed desks. Educators filled those orders from school districts in 30 states. One of its most popular products was the Porta-Lab, a freestanding cabinet with a sink and gas lines for Bunsen burners that continued to be used in high school science classes around the nation for decades after they rolled off the production line.

Tacoma’s furniture-making industry would all but disappear between the 1960s and 1980s, however, as logging operations and saw mills closed, making the price of its raw materials more expensive. Cheaper options from Asia made locally crafted furniture more of a luxury than utilitarian pieces for working-class homes. Tacoma firms merged and moved away or simply closed. Furniture that was once something families had handed down through the generations was being replaced with boxes of unfinished pine cabinets and desks that budget-minded customers had to put together themselves.